What is a Velocity Ratio of Screw Jacks?

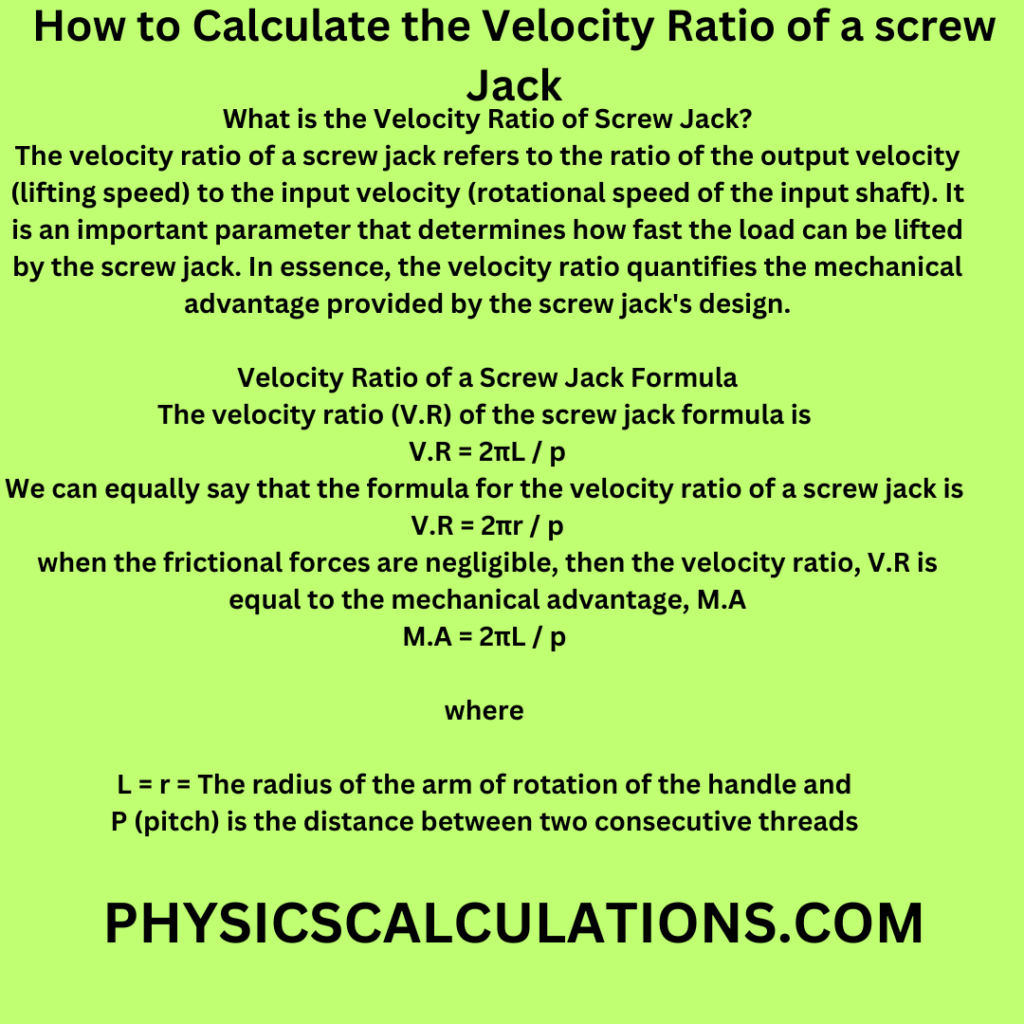

The velocity ratio of a screw jack refers to the ratio of the output velocity (lifting speed) to the input velocity (rotational speed of the input shaft). It is an important parameter that determines how fast the load can be lifted by the screw jack. In essence, the velocity ratio quantifies the mechanical advantage provided by the screw jack’s design. In this article, I will apply simple steps to help you understand how to calculate the velocity ratio of a screw jack. You can also watch a comprehensive video explanation to deepen your understanding of the topic. Screw jacks are indispensable mechanical devices used for lifting heavy loads with precision.

Among the critical aspects that define their efficiency and performance, the velocity ratio plays a very important role.

Below, is a video explanation of velocity ratio and how to calculate the velocity ratio of a screw jack

Velocity Ratio of a Screw Jack Formula

The velocity ratio (V.R) of the screw jack formula is V.R = 2πL / p

We can equally say that the formula for the velocity ratio of a screw jack is

V.R = 2πr / p

when the frictional forces are negligible, then the velocity ratio, V.R is equal to the mechanical advantage, M.A

Thus.

M.A = 2πL / p

where

L = r = The radius of the arm of rotation of the handle and

P (pitch) is the distance between two consecutive threads

Examples of How to Calculate the Velocity Ratio of a Screw Jack

Here are a few examples of how to calculate the velocity ratio of a screw jack

Example 1

A screw jack whose pitch is 4.4 mm is used to raise a body of mass 8000kg through a height of 20cm. The length of the jack is 70cm. If the efficiency of the jack is 80%, calculate the velocity ratio of the jack.

Solution

Data:

Pitch, p = 4.4mm = 0.0044m (by converting the millimeter to the meter)

Length, L = 70 cm = 0.7m (by converting the millimeter to the meter)

π = 22/7

and the formula for the velocity ratio of a screw jack is

V.R = 2πL / p

substituting our data into the above formula, we now have

V.R = 2πL / p = ( 2 x 22/7 x 0.7 ) / 0.0044 = ( 2 x 22 x 0.7 ) / 7 x 0.0044

We can now write the above expression as

V.R = 30.8/0.0308 = 1000

Example 2

A screw jack with a pitch of 0.5cm and the handle of the screw jack is 2cm long. Determine the velocity ratio of the screw jack. Considering the efficiency of the screw to be 35%.

Solution

Data:

pitch, p = 0.5cm

Length, L = 2cm

and the formula for velocity ratio of the screw jack is

Velocity Ratio = 2πL / p

Velocity Ratio = = 2π x 2 / 0.5 = 25

Example 3

The pitch of a screw jack is 0.5cm. The arm is 50cm long and it is a mechanical advantage is 250. Calculate it is velocity ratio.

Solution

Data:

Pitch, p = 0.5 cm

Length, L = 50 cm

we now apply the formula below

Velocity Ratio = = 2πL / p

Thus,

Velocity Ratio = = (2π x 50) / 0.5 = (2 x 22/7 x 50) / 0.5 = (2 x 22 x 50) / 7 x 0.5 = 2,200 / 3.5 = 628.57

Example 4

Calculate the velocity ratio of a screw jack of pitch 0.3cm if the length of the tommy bar is 21cm.

Solution

Data:

pitch, p = 0.3cm

length, L = 21cm

And the formula for the velocity ratio of a screw jack is 2πL / p

We substitute our data into the above formula

V.R = 2πL / p = (2 x π x 21) / 0.3 = (42 / 0.3) x π

Thus,

V.R = 140 x π = 140 x (22/7) = (140×22)/7 = 3,080/7 = 440

Optimizing the Velocity Ratio for Efficiency

Achieving an optimal velocity ratio is essential for efficient and reliable screw jack performance. Here are some practical tips for optimizing the velocity ratio:

- Thread Design: The thread pitch and lead of the screw play a significant role in determining the velocity ratio. Choose thread designs that align with your load and speed requirements.

- Gearbox Selection: Gearboxes can be incorporated into screw jack systems to modify the input speed and, consequently, the velocity ratio. Careful selection of gear ratios is crucial.

- Load Consideration: Understand the weight of the load and the desired lifting speed. Adjust the velocity ratio accordingly to strike a balance between speed and precision.

- Efficiency Factors: Consider factors such as friction, lubrication, and mechanical losses, which can influence the actual velocity ratio compared to the theoretical calculation.

FAQs

How does the velocity ratio affect lifting speed?

The velocity ratio directly influences how fast a load can be lifted or lowered by a screw jack. A higher velocity ratio results in faster lifting, while a lower ratio offers more precision.

Can the velocity ratio be greater than 1?

Yes, the velocity ratio can be greater than 1. This indicates that the output velocity (lifting speed) is higher than the input velocity (rotational speed), providing a mechanical advantage.

What is the trade-off between velocity ratio and precision?

Higher velocity ratios offer faster lifting speeds but may compromise precision. Lower ratios prioritize precision but result in slower lifting.

Is the velocity ratio constant for all screw jacks?

No, the velocity ratio can vary based on factors like thread pitch, lead, gearbox use, and load. It’s essential to calculate or determine the ratio for each specific screw jack application.

How can I enhance the velocity ratio without sacrificing precision?

To enhance the velocity ratio without sacrificing precision, consider using gearboxes with appropriate gear ratios. These can amplify input speed while maintaining control over the lifting process.

What role does lubrication play in velocity ratio optimization?

Lubrication reduces friction, enhancing overall efficiency. Proper lubrication can contribute to achieving the desired velocity ratio while minimizing energy losses.

You may also like to read:

How to Calculate Velocity Ratio of an Inclined Plane

Reference