Introduction

When it comes to the physical world around us, it is very important to know how to measure force. In various scientific and engineering fields, accurately measuring force is of utmost importance. Whether you’re conducting experiments, designing machinery, or analyzing structures, having the knowledge of measuring force is very important.

In this comprehensive guide, we will delve into the intricacies of force measurement, exploring different methods, tools, and techniques. So, let’s embark on this journey of understanding the measurement of force!

How to Measure Force: Explained

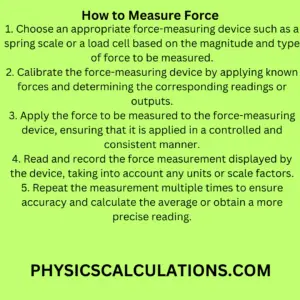

Measuring force involves determining the interaction or push/pull effect applied to an object. The instrument commonly used for this purpose is a force measuring device called a force gauge. Here is a simple guide on how to measure force:

- Select a Force Gauge: Choose an appropriate force gauge based on the expected force range. Force gauges come in various types, such as spring scales, hydraulic gauges, or electronic load cells.

- Zero the Gauge: Ensure the force gauge reads zero when no force is applied. This calibration ensures accurate measurements.

- Attach the Object: Securely attach the force gauge to the object or point where the force needs measurement. Ensure a direct and single-point application for precise readings.

- Apply Force: Exert force in the desired direction. Read the force value directly from the gauge’s display or scale. Some electronic force gauges may provide digital readings.

- Take Multiple Readings: For accuracy, take multiple readings and calculate the average. This helps mitigate any fluctuations or errors.

- Consider Units: Note the units of force, commonly measured in newtons (N) or pounds-force (lbf), depending on the force gauge.

- Record Results: Record the measured force along with any relevant details like direction or duration of the force application.

Measuring force accurately is very important in various fields, from physics experiments to industrial applications. Using a suitable force gauge and following these steps ensures reliable and consistent force measurements.

The Concept of Force

Before we dive into the details of force measurement, it’s important to have a clear understanding of what force actually is. In physics, force is defined as an interaction that causes an object to accelerate, change its shape, or experience deformation.

Additionally, force is a vector quantity, which means it has both magnitude and direction. Forces can be categorized into various types, including gravitational, electromagnetic, and mechanical forces.

The Importance of Force Measurement

Force measurement plays a huge role in numerous fields and industries. From ensuring product quality and safety to optimizing performance and efficiency, accurate force measurement is indispensable. Here are some of the key areas where measuring force is very important:

1. Structural Engineering

In structural engineering, measuring forces is essential to assess the integrity and stability of buildings, bridges, and other structures. Therefore, we can accurately measure forces such as compression, tension, and shear, to ensure the safety of these structures and make informed decisions regarding design and maintenance.

2. Material Testing

The knowledge of mechanical properties of materials is important in industries such as manufacturing, aerospace, and automotive. Thus, force measurement allows you to determine factors like tensile strength, yield strength, and elasticity. It enables you to select the right materials for specific applications.

3. Biomechanics

In the field of biomechanics, the knowledge of measuring force helps researchers and medical professionals gain insights into human movement, joint forces, and muscle activation patterns. Therefore, this knowledge is valuable for designing prosthetics, optimizing sports performance, and diagnosing and treating various musculoskeletal conditions.

4. Product Testing

Force measurement is integral to product testing across various industries. From electronics and consumer goods to pharmaceuticals and food production, measuring forces ensure that products meet quality standards and regulatory requirements. Therefore, it helps identify weaknesses, improve durability, and enhance overall product performance.

Now that we have established the importance of force measurement, it is time to look into the various methods and techniques we use in this field.

Methods of Force Measurement

1. Direct Measurement

Direct measurement involves using a force sensor or load cell to directly measure the force applied to an object. Load cells are transducers that convert force into an electrical signal, which can be easily measured and recorded. Therefore, these devices are designed to accurately capture forces in various directions and magnitudes, making them widely used in industries and research applications.

2. Indirect Measurement

Indirect measurement techniques involve inferring force indirectly based on other measurable quantities. Some common indirect measurement methods include:

i. Strain Gauge Technique

The strain gauge technique relies on the principle that the deformation of a material is directly proportional to the applied force. By attaching strain gauges to a structure or object, the resulting strain can be measured, allowing for the calculation of the applied force.

ii. Pressure Measurement

In certain applications, the force can be inferred by measuring the pressure exerted by a fluid or gas. This method is commonly used in hydraulic and pneumatic systems, where pressure sensors provide an indirect measurement of the force applied.

3. Calibration and Accuracy

Regardless of the measurement method employed, calibration is crucial to ensure accuracy and reliability. Calibration involves comparing the output of a measuring instrument to a known standard to determine its accuracy and make necessary adjustments.

Frequently Asked Questions

1. How to measure force using a load cell? To measure force using a load cell, follow these steps:

- Step 1: Mount the load cell appropriately to ensure accurate force measurement.

- Step 2: Apply the force to the load cell, ensuring it is within the load cell’s specified range.

- Step 3: Connect the load cell to a data acquisition system or measuring instrument.

- Step 4: Read and record the force measurement displayed by the instrument.

2. What are the advantages of using strain gauges for force measurement? Strain gauges offer several advantages for force measurement:

- They can measure forces in multiple directions.

- They have high sensitivity and accuracy.

- They are cost-effective and readily available.

- They can be easily integrated into various structures or objects.

3. What are some common applications of force measurement in sports? Force measurement finds applications in sports biomechanics, including:

- Analyzing the force exerted during running, jumping, and throwing.

- Optimizing equipment design, such as athletic shoes and sports gear.

- Studying the impact of force on injury prevention and rehabilitation.

4. How does force measurement contribute to quality control in manufacturing? Force measurement ensures product quality in manufacturing by:

- Verifying the strength and durability of components and materials.

- Detecting defects, such as weak welds or improper bonding.

- Assessing the performance and reliability of manufactured products.

5. What are the factors to consider when selecting a force measurement device? When choosing a force measurement device, consider the following factors:

- Required force range and measurement accuracy.

- Environmental conditions, such as temperature and humidity.

- Compatibility with the data acquisition system or software.

- Long-term stability and reliability of the device.

6. Can force measurement be used in medical applications? Yes, force measurement is extensively used in medical applications, including:

- Orthopaedic research and joint biomechanics.

- Prosthetic design and evaluation.

- Rehabilitation and physical therapy assessments.

- Monitoring and analyzing human movement patterns.

Conclusion

Understanding the methods of measuring force is important in various scientific, engineering, and industrial domains. Accurate force measurement enables us to ensure product quality, optimize performance, and enhance safety. In this comprehensive guide, we looked into the concept of force, the importance of force measurement, and different methods and techniques employed in this field.

By employing direct or indirect measurement methods and considering calibration and accuracy, professionals can obtain precise force measurements for their specific applications.

You may also like to read: